Factories and industries across the globe are searching for ways to get maximum productivity at minimum cost. It is here that they search for cost-effective solutions for manufacturing and production. Machines play an important role in helping industries save time with manual processes. Some several businesses and industries work with metal cutting. They need to shape the metal to its precise shape and measurement.

This is where they need special cutting machines to do the work for them. Workers take time, and it is here that special machines are required for the task.

How does precision machining bring immense value to a business?

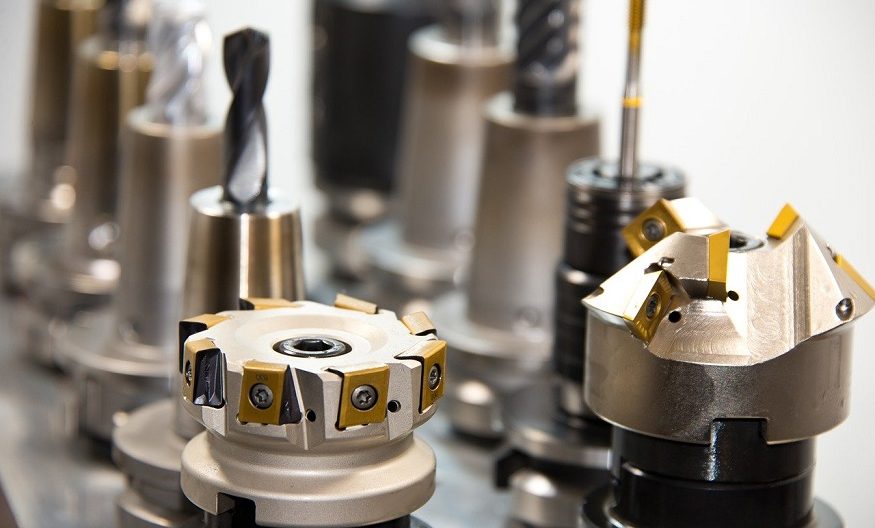

Precision machining is indispensable to most advanced industries today. It is the process where material can be removed from any workpiece while its close tolerance finish is held. There are several types of precision machines, including those for turning, milling, and electrical discharge. This machine is generally controlled with the use of numerical controls from a computer or CNC (computer numerical controls)

Take a look at the bio-medical, aeronautical, metrological, and other advanced industries today. They need products that are precisely cut, shaped, and functional in every aspect. The dimensional measurements should be accurate. This is where the above process comes into play. With the help of companies specializing in precision machining, industries can get functional parts that are high in integrity and quality.

How does this process work?

The process deploys the use of tools applied for several industrial applications. Most industries have to process the raw materials themselves. This makes the final product functional and applicable to the specific need of the industry. Here, the raw material is transformed into the specific type of component that is either utilized further or placed together in other machines in the particular application or task.

Boost integrity and quality

With precision machine processes, every manufacturing unit of a business can boost its integrity and quality. Large bulky chunks of metal can be reshaped into sleek and refined parts. Excess material is removed to increase its levels of tolerance. Developed and advanced industries have changed the way modern industries function. Multiple products are made from the same source material. Industries technologies have redefined the way factories and manufacturing units function and produce various products. It gives industries-

- Efficiency in operations

- Accelerated speed

- Lesser risks

- Lowers costs of production

- Faster production

Therefore, precision machining aims at giving manufacturing units a very high level and degree of accuracy. This process is automated. This boosts safety and keeps the operator of computer numerical controls out of the way. It is cost-effective for most industries and gaining immense popularity in modern times.

Read more: Gia Walsh Bronxville – How Can You Become a Successful Movie Producer

Some companies specialize in the above process. One can contact them for getting manufactured parts with precision. These companies have years of valuable experience in the field, and you can check their websites for getting an idea about the industries they serve. You can contact them with your requirements and request them for a price quote before placing your order.